By Martin Vassilev / 13 Aug, 2025

Cross-docking is a powerful logistics strategy that has been transforming supply chain operations for decades. By eliminating or significantly reducing storage time in warehouses, businesses can accelerate product movement, cut costs, and boost customer satisfaction. But is cross-docking right for your business? Let’s break down the process, benefits, challenges, and best practices so you can make an informed decision.

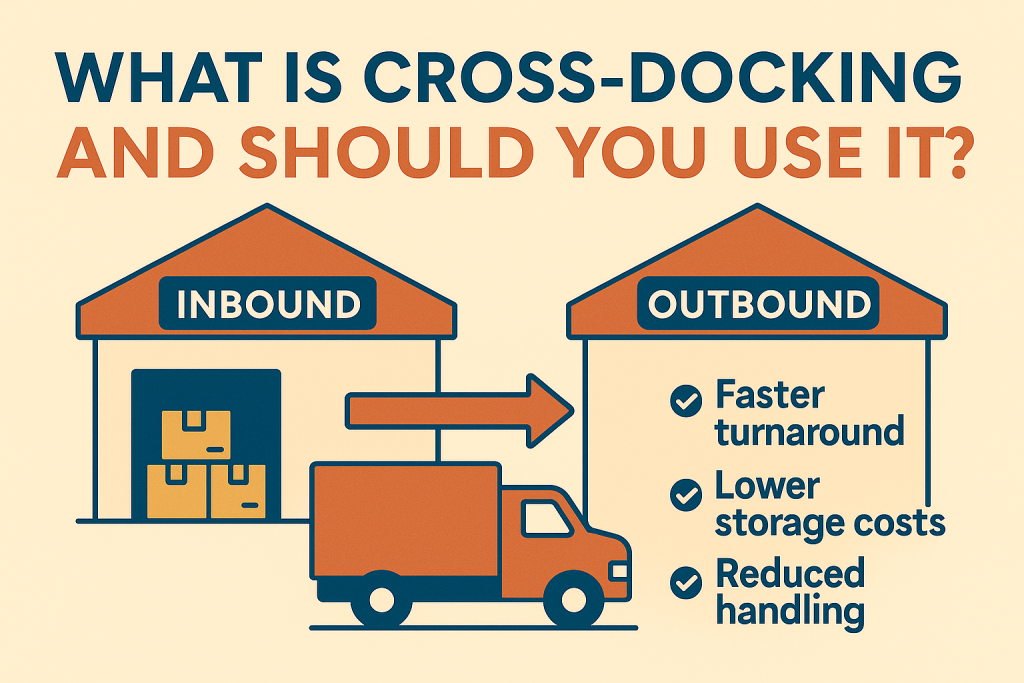

Cross-docking is a distribution system where inbound goods from suppliers or manufacturers are directly unloaded from incoming trucks or containers and loaded onto outbound vehicles for delivery, with minimal or no storage in between. Instead of sitting in a warehouse for days or weeks, products pass through a cross-dock terminal within hours.

This method is widely used in industries such as retail, e-commerce, food distribution, automotive, and pharmaceuticals—where speed, freshness, and efficiency are critical.

While there are variations in implementation, most cross-docking processes follow these steps:

Inbound Shipment Arrival

Suppliers deliver goods to a designated cross-docking facility.

Unloading and Sorting

Products are unloaded and immediately sorted based on final destinations or customer orders.

Transfer to Outbound Dock

Items are moved directly to outbound shipping areas without being placed into storage.

Loading for Delivery

Orders are loaded onto outbound trucks for immediate transportation to retailers, customers, or other distribution points.

Goods are pre-sorted by suppliers based on customer orders before arriving at the facility. The terminal simply consolidates them for delivery.

Sorting happens at the cross-docking facility after goods arrive, allowing for greater flexibility and last-minute order changes.

Used when demand aligns with available products in real time, making it perfect for handling urgent or high-priority shipments.

Because products spend less time in the warehouse, you save significantly on storage and handling fees. This aligns with principles outlined in lean warehousing.

Goods move quickly through the supply chain, helping you meet customer expectations for same-day or next-day delivery.

Less need for bulk storage means reduced risk of overstocking or dead inventory, an issue addressed in real-time inventory management.

Fewer touchpoints mean reduced labor requirements for storage, picking, and inventory control.

Ideal for perishable goods, pharmaceuticals, and high-demand retail products, as it minimizes handling time and exposure to damaging conditions.

Since there’s little room for delays, coordination with suppliers, carriers, and distributors is critical.

Fragile goods, custom-made products, or those requiring long-term storage may not benefit from this method.

Cross-docking facilities require specialized layouts, conveyor systems, and dock configurations.

Without accurate tracking and data analytics, cross-docking can lead to misrouted shipments. Leveraging advanced solutions like AI in logistics can help.

Cross-docking is ideal if:

Your products have a short shelf life (e.g., food, flowers, pharmaceuticals).

You operate in high-demand sectors like e-commerce or fast-moving consumer goods (FMCG).

You want to cut warehousing costs and speed up delivery.

Your supply chain partners are reliable and time-sensitive.

You already use advanced inventory and order management systems.

However, if your business relies heavily on made-to-order products or has unpredictable supply schedules, traditional warehousing may still be more effective.

Use warehouse management systems (WMS), transportation management systems (TMS), and real-time tracking to coordinate operations effectively.

Design your facility for efficient unloading, sorting, and reloading to minimize handling time.

Maintain consistent communication with suppliers to ensure timely deliveries.

Even with speed, quality assurance is vital to prevent damaged or incorrect shipments.

Integrate cross-docking with other efficiency strategies such as warehouse automation or supply chain optimization for maximum impact.

| Feature | Cross-Docking | Traditional Warehousing |

|---|---|---|

| Storage Time | Hours or less | Days to months |

| Cost Efficiency | Lower storage costs, higher setup cost | Higher storage costs, lower setup |

| Delivery Speed | Very fast | Slower due to storage phase |

| Inventory Management | Just-in-time | Stockpiling possible |

| Best For | Perishable goods, high turnover items | Bulk stock, seasonal inventory |

Retail Chains: Speed replenishment and reduce out-of-stock incidents.

E-commerce: Meet same-day delivery expectations.

Grocery and Food Distribution: Keep products fresh.

Pharmaceuticals: Ensure timely delivery of life-saving drugs.

Automotive: Streamline parts distribution to manufacturing plants.

Cross-docking is a proven strategy for streamlining supply chains, cutting costs, and improving delivery times—especially for businesses handling high-demand or perishable goods. When combined with modern technology and strong supply chain partnerships, it can give you a competitive edge in today’s fast-paced market.

If you want to explore how cross-docking could transform your business, contact us today via our Customer Service page for a tailored logistics solution.

“Thanks to Byexpress all my shipping and fulfillment costs are in line now”

“All my issues were solved by Byexpress team that I had with pervious 3pl provider.”

“Thank you Byexpress team could not done it without you guys.”

“Their integration and customer service were the key for me”

“Outstanding delivery service! The package was well-packaged, and

the delivery team was professional and courteous”

“Great and knowledgeable team to work with.”

Thanks, guys, for reducing my shipping rates

Ottawa Office

2411 Holly Lane

Ottawa, ON, K1V 7P2

Toronto Office

13-280 West Beaver Creek Road Unit #136

Richmond Hill, ON, L4B 3Z1

Alexandria Office

173 Kenyon Street West

Alexandria, ON, K0C 1A0

Montreal Office

4388 Saint-Denis Street Unit #200

Montreal, QC, H2J 2L1

California Office

155 North Riverview Drive

Anaheim Hills, CA, 92808

Call Us

Toll-Free: 1-866-744-7122

Local : 613-739-3000

Email Us

Multilingual Services